Who We Are

Agile Plant Solutions Inc (APS) is a Virginia based company focusing on the innovations for manufacturing. APS creates technologies that help improve profitability to manufacture on-shore. APS helps enabling flexible manufacturing and Lean Six Sigma quality control for manufacturing facilities to improve efficiency and lower production cost.

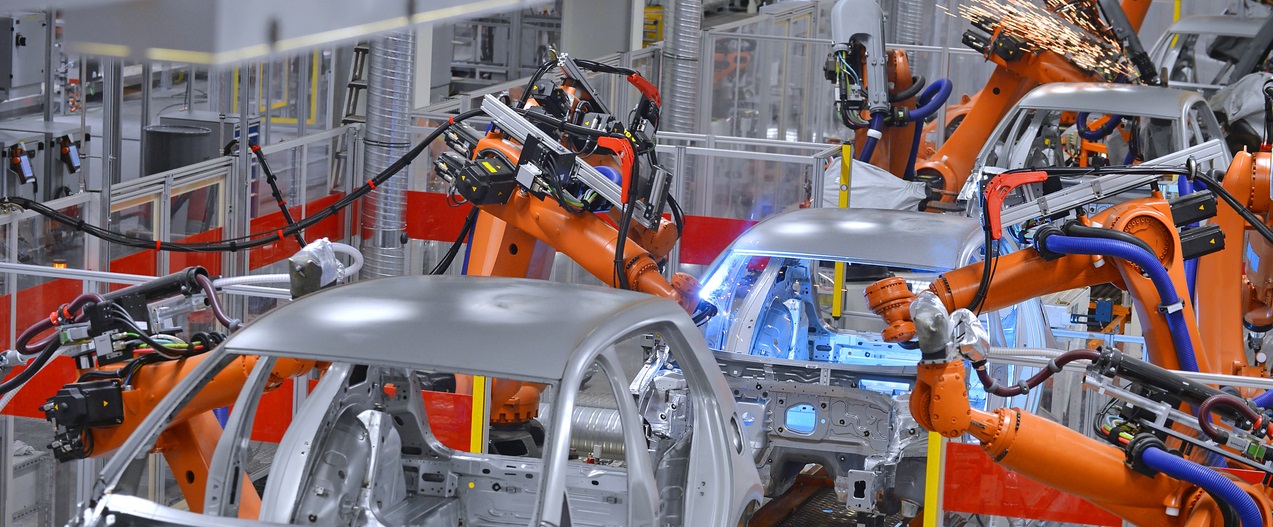

APS offers Manufacturing Execution System (MES) solutions to manufactures of machinery and electronics products, particularly in the auto industry and electronics industry. APS iPlant™ MES solutions enable manufactures achieving productivity, quality, and flexibility with their production operations.

☞

History of Agile Plant Solutions

2007 Initial concept, modeling, architecture finished.

2009 Deployment in several TRW auto part factories in Europe and Asia.

2012 Expanding into electronics industry.

iPlant™ MES

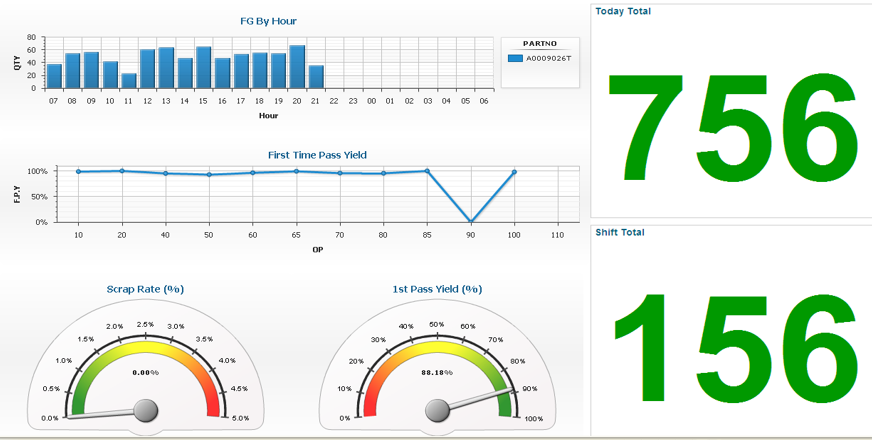

iPlant™ MES facilitates productivity and quality management of manufacturing facilities. iPlant™ MES contains the following key components.

See below for more details.iPlant™ Productivity

iPlant™ Productivity is an essential part of the standard iPlant™ MES suite. This product module provides key functions that support flexible manufacturing.

Manufacturing on-shore has seen the strong trend to incorporate flexibility in the manufacturing process, and to enable manufacturing facilities to quickly adjust towards meeting market demands. Flexibility in manufacturing, allows manufacturers switch gears to produce with differing production capacities and product types. Being able to quickly adjust to the demand fluctuations makes the on-shore manufacturing critically valuable to business. To achieve flexibility in manufacturing, assembly lines must be rapidly configured and reconfigured to produce different product models with different configurations, or even different product types. iPlant™ Productivity helps manufacturers achieve this flexibility through rapid assembly line configuration and re-configuration features. Out of box, iPlant™ Productivity provides:

- Assembly line digital configurations

- Assembly line monitoring

- Andon system

- OEE, downtime, and KPI dashboard

- Resource management (material, devices and operators)

iPlant™ Quality

iPlant™ Quality is the quality management component of the standard iPlant™ MES suite. This module provides statistical functions to support the quality control for manufacturing processes.

iPlant™ MES has connectivity to an exhaustive array of manufacturing devices, allowing the system to gather every aspect of manufacturing data in real time. iPlant™ Quality allows manufacturers to instantly define data collection points along the steps of manufacturing processes. Moreover, the data gathered across the assembly lines are organized into a centralized data warehouse that supports standardized quality control functions. Out of box, iPlant™ Quality provides:

- Automated data collecting

- Statistical process control tools

- Lean Six Sigma and ISO 9001 quality control processes

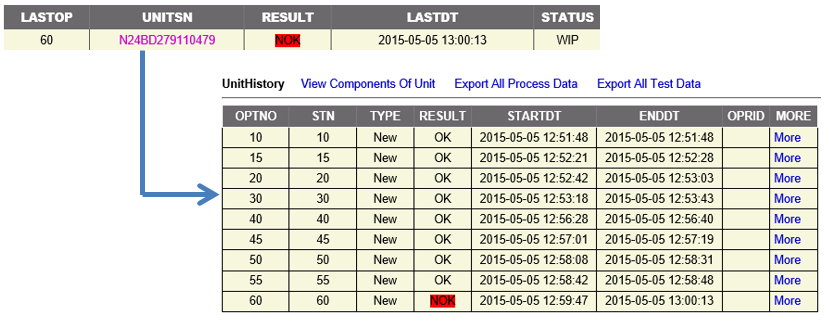

iPlant™ Traceability

iPlant™ Traceability enables manufacturers to quickly identify source of defects.

iPlant™ MES system manages the product marking through part serial numbers, which could be in RFID, Laser marks, or QR codes. With the mappings among the connected serial numbers tracked by the system, manufacturers can easily trace defected products and raw materials from their suppliers. Quality issues can thus be effectively tracked down to the root causes and corrective actions be taken. Through iPlant™ Traceability, manufacturers may also save unnecessary costs for recalls as they can identify and isolate the defected products/batches from the rest. Manufacturers also gain quantified knowledges to evaluate the quality of their suppliers, through the established traceability of the materials. With traceability, manufacturers thus benefit from both lower costs for recalls and better product quality controls. Out of box, iPlant™ Traceability provides:

- Marking and scanning

- Label printing and management

- Easy queries and reports

iPlant™ Connects

Extensive connectivity functions allow iPlant MES modules to integrate with the legacy enterprise systems with ease. iPlant™ MES components can each serve as OEM MES function modules to work within an existing legacy MES system. This has been proved to be an effective track to incorporate iPlant’s features into an existing MES infrastructure. Out of box, iPlant™ Connects provides standard connectors to feed data and web service to leading ERP products, including SAP ERP, Oracle ERP, and even some popular open source products.

iPlant™ MES suite has been developed with a modern service orient design. The SOA architecture allows us to effectively integrate iPlant MES with legacy system environment. Meanwhile, art of state technology means iPlant system would relieve the manufacturers from pressing IT upgrade needs for the coming years.

IT Consulting

APS commits to providing one-stop IT service to support manufacturing operations. APS engages in a broad range of operation supports including software development, IT, data analysis, network administration, etc.

- Develop software used in manufacturing plants

- Enterprise system maintenance and administration

- Data program pertaining to quality and productivity management

- Network and cyber-security management for manufacturing facilities

APS consulting offers several benefits to accommodate IT needs pertaining to a manufacturing environment.

- APS provides flat rate contracting hours, 24 x 7, on-site and off-site.

- APS allows clients to customize IT service based on their individual needs.

- APS offers quality service to our clients at an efficient cost structure, through optimized utilization of our on-shore and off-shore talent resources.

Use Case - enhance quality control with iPlant MES in auto parts industry

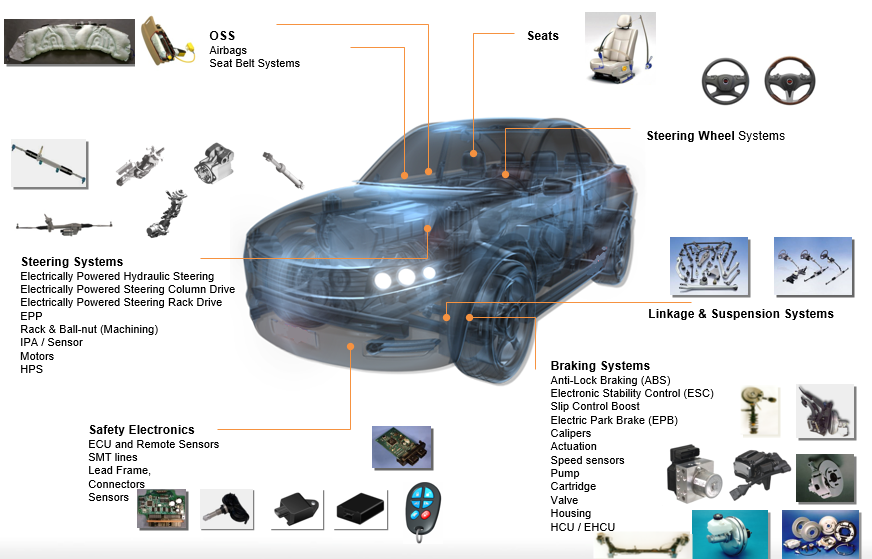

Through many years of service to the auto part industry, APS has enabled all types of assembly lines for the auto part industry and is emerging as the leading MES supplier to the auto part industry.

iPlant™ MES is powering every type of assembly lines in the auto parts industry, producing finished goods ranging from linkage and suspension systems, steering systems, to safety electronics, and to airbags, breaking systems, so on and so forth.

Our Clients

APS focus on providing cost effective services to several major manufacturing industries, including the auto industry, the electronics industry, and the Oil & Gas industry. Companies well known in these industries are achieving exciting results using iPlant MES solutions.

US Headquarters

E-mail:

Phone:

1-571-242-3506

Mail:

Freddie Lan

Agile Plant Solutions

P.O. Box 103

Fairfax, VA 22038-0103

Area Support Centers

| Area | Office Phone | |

|---|---|---|

| US | 1 (571) 242 – 3506 | service@agileplant.net |

| Canada | 1 (647) 667 – 8978 | service.ca@agileplant.net |

| China | 86 (021) 5423 – 1685 | service.cn@agileplant.net support@iplant.com.cn |